World Leader in Quick

See Incodema Capabilities and Resources

Phone: 607-277-7070 1920 Slaterville Rd, Ithaca, NY 14850

Who is Fathom Digital Manufacturing? One of the largest on-demand digital manufacturing platforms in North America.

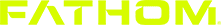

Sheet Metal Prototyping Solutions

Your design is unique. Your prototyping solution should be too.

Metal Cutting & Precision Forming

Our team of experts will develop custom metal fabrication solutions to meet your needs.

ITAR Registered

We have passed all ITAR certification audits and have proven to exceed ITAR criteria for all our operating and inspection systems.

Tailored to Industry-Specific Needs

We drive to hit our customer commitments every time.

Incodema Capabilities

Jump to: Cutting | Precision Forming | Mid-to-High Volume | Post Processing & Finishing

We offer a variety of cost-effective, semi-automated tooling solutions that cost 15-30% of fully automated production tooling.

- Photo Chemical Machined Flat Blanks – Small, thin parts with complex flat geometry are manufactured burr free and ready for forming.

- Put-and-Take Tooling – Semi-complex dies, actuated manually or by machine, form complex features and/or multiple bending operations in one step.

- Die Blanking – Flat parts and some parts with formed features may be manufactured complete in full automation or made ready for secondary, semi-automated bending and forming processes.

Our in-house welding experts can complete your part by fusing two or more parts together through heat, pressure or both.

- Arc welding

- Metal inert gas (MIG)

- Tungsten inert gas (TIG)

- Resistance Spot Welding

- Laser Welding

- Oxyfuel Welding and Cutting

Incodema Resources

About Incodema

Incodema is the industry leader in precision sheet metal engineering solutions for all the major market sectors of our economy, including electronics, defense, aerospace, life sciences and industrial. Based in Ithaca, NY Incodema by Fathom is a turnkey single source provider of all necessary services required to manufacture your parts from inception through completion.

Our comprehensive portfolio of manufacturing services allows us to support several material types giving us the flexibility and agility to serve our customers from prototype through production. As part of Fathom Digital Manufacturing, Incodema has access to a robust nationwide network of comprehensive additive and advanced manufacturing capabilities.

By leveraging technology through the latest advancements in innovative manufacturing equipment, Incodema looks forward to the opportunity to demonstrate our synergistic approach to finding the right manufacturing process for your project.

Benefits of Creating a Sheet Metal Prototype

A sheet metal prototype can help eliminate the guesswork in manufacturing while reducing overall costs. Prototypes work as a physical example of a concept, making it easy to explain product features and benefits. Functional prototypes also allow for form, fit and function testing. A prototype allows a product or part to be evaluated to guarantee that it is to exacting specifications. By testing your design before mass manufacturing, material waste, labor, and costs can be reduced. Prototyping allows designers and engineers to learn more about the new product and enables the creation of marketing assets like photography and instructional manuals.

How Does Sheet Metal Prototyping Work?

The first step is to ensure your design is suitable for the manufacturing process. Any number of sheet metal fabrication processes may be used to create your prototype from cutting processes to forming processes to finishing processes. The team of engineering experts at Incodema by Fathom will work with you to determine the best solution.

Rapid Sheet Metal Delivery Times

Need a part fast? Incodema specializes in rapid production. Standard lead times are below, but 24hr expedite options are available.

| Parts | Delivery time |

| 1-50 flat part pieces | 2 days |

| 50-1,000 flat part pieces | 5-7 days |

| 1-500 formed parts | 6-8 days |

| 1-5 drawn part pieces | 10-15 days |

| 4 slide tooled parts | 4-6 weeks |

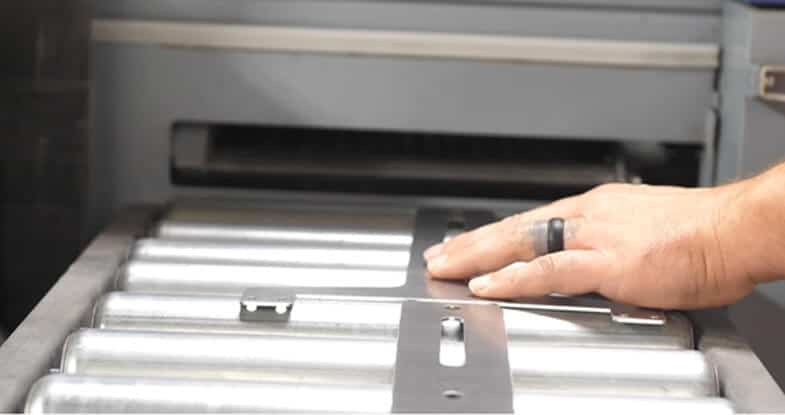

Cutting Solutions for Sheet Metal Prototypes

Incodema by Fathom leverages powerful technologies to streamline the cutting process and handle even the toughest, high-value cutting challenges.

- Laser Cutting: Perfect for high-quality prototyping and low to high volume production, laser cutting is a highly accurate process that yields excellent cut quality with minimal heat-affected zones

- Microcut™: Suitable for a wide variety of thin materials, Microcut uses abrasive waterjet technology with higher cutting accuracies and very tight tolerances

- Waterjet Cutting: Ideal for applications that require thickness up to 6 inches, Waterjet uses a CNC machine process that can cut titanium, Inconel, brass, tool steel, glass, stone, ceramics, and more.

- Photochemical Machining/Etching (PCM): Ideal for thin parts with complex geometries and many features, PCM selectively removes material using a chemical action.

- Wire Electrical Discharge Machining (EDM): EDM uses electrical currents to cut complex contours into pre-hardened steel. EDM is perfect for highly detailed prototypes.

Cutting Specifications

| Material Thickness | Tolerance | Kerf | Part Volume | Set Up Cost | Lead Time ** | Notes | |

| OMAX WATERJET | Up to 6″ | 0.005″- 0.015″ | .020″/.040″ | 1 to 5,000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, Kevlar, carbon fiber, ceramics, etc. Taper up to 59° |

| MICROCUT™ | .0005″ – 0.5″ | 0.0005″ -0.005″ | 0.009″, 0.011″, 0.0196″ | 1 to 5,000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, Kevlar, laminates, carbon fiber, ceramics, etc. |

| FIBER LASER | AL: 0.250″ SS: 0.375″ CRS: 0.500″ COP: 0.250″ Brass: 0.125″ | 0.002″ – 0.005″ | .008″ | 1 to High-Volume | Low | 6-8 days | Metals – Fast |

| WIRE EDM | 0.001″ – 6″ | 0.0005″ | 0.005″ | 1-200 Is Best | Low | 6-8 days | Conductive Metals, Carbon |

| * CHEM ETCH | 0.005″ – 0.060″ | Is +/- 10% of material thickness, .002″ min. | Equal to metal thickness | 1- Infinity | $350 Min. | 6-8 days | Metal Only. No Burrs. Beveled Edges. Half Etch and Holes. |

*Inner radius should be 100% of material thickness. Outer Radius should be 75% of material thickness.

**Dependent on geometry, volume and material: 24hr Expedite options available.

Precision Forming: Prototype to Low-Volume

Need precision forming? At Incodema, we have developed a technique in which we turn an ordinary press brake into a manual progressive die. By combining this dynamic technique with our custom tooling made with in-house toolmakers, we can easily achieve even the most intricate and complex design specifications. In fact, this process is so precise that we refer to it as “sheet metal origami” on the shop floor.

Large Format Parts and Prototypes

While small, complex parts are our specialty, we also offer large format services in-house. We maintain a 300-Ton Press with a 36” x 72” bed in our Newark, New York facility to form parts that are too large for a traditional press brake. This equipment is ideal for small volume projects that require deep-drawn custom parts or large die sets with embosses and gussets.

Mid to High Volume Production

Looking for more volume? No problem. Our mid to high volume solutions take advantage of lower tooling and setup costs than progressive die manufacturing and can include custom features such as gussets and embosses. All our tooling is designed and built entirely in-house, making Incodema your turnkey manufacturing supplier.

A few of our unique processes below:

Semi Automated Manufacturing

Looking for mid-to-high volume quantities? We offer a variety of cost-effective, semi-automated tooling solutions that cost 15-30% of fully automated production tooling.

- Photo Chemical Machined Flat Blanks – Small, thin parts with complex flat geometry are manufactured burr free and ready for forming.

- Put-and-Take Tooling – Semi-complex dies, actuated manually or by machine, form complex features and/or multiple bending operations in one step.

- Die Blanking – Flat parts and some parts with formed features may be manufactured complete in full automation or made ready for secondary, semi-automated bending and forming processes.

Four-Slide and Multi-Slide

Four slide and multi-slide manufacturing is ideal for small and intricate springs, brackets, electrical terminals, clips and battery contacts in high volume quantities. All tooling is designed and built in-house by the Incodema by Fathom team.

Specialty Stamping

Our skilled and creative toolmakers design and create complex tooling solutions necessary to manufacture even the most challenging stamped parts. Many of Incodema’s hands-on operators possess engineering skills, and they are empowered to develop manufacturing solutions on the fly to keep the manufacturing process moving quickly and smoothly.

Post-Processing and Finishing

Post-processing and finishing is the essential final step of the manufacturing process. Most parts will require some sort of smoothing or painting when they come off a machine. Post-processing improves the quality of parts and ensures that they meet all their design specifications.

Welding Processes

Our welding experts can complete your part by fusing two or more parts together through heat, pressure or both.

Incodema’s Welding Processes:

- Arc Welding

- Metal Inert Gas (MIG)

- Tungsten Inert Gas (TIG)

- Resistance Spot Welding

- Laser Welding

- Oxyfuel Welding and Cutting

Outside Processing

We maintain strategic partnerships with key suppliers of heat treating, plating and powder coating who understand our need for quality and speed. As part of the Fathom Manufacturing Platform, Incodema has access to a robust nationwide network of comprehensive additive and advanced manufacturing capabilities. Fathom Manufacturing’s extensive certifications include ISO 9001:2015, ISO 9001:2015 Design, ISO 13485:2016, AS9100:2016, NIST 800-171 and ITAR.

Post Machining

While we make every effort to meet all customer design specifications during the fabrication process, occasionally post CNC machining is required to complete the part. Our in-house CNC machining centers allow us to post-mill features into your sheet metal components to successfully manufacture your parts while maintaining our fast turnaround times.

In-House Custom Tooling

Whether your formed parts need intricate EDM tooling, waterjet cut tools, or more robust CNC machined tooling, our team of engineers and master tool makers can develop creative tooling solutions for your formed parts. Complex bending and precision are our specialty and we look forward to solving your most challenging design features.

Deburring and Finishing

Attention to detail is critical to our manufacturing process, and we can uniformly remove laser dross, mechanical burrs or sharps and other surface imperfections with our in-house deburring and finishing operations. Our processes range from hand sanding to automated deburring, tumbling and finishing equipment.

ITAR Registered for Regulated Parts

Incodema Inc. is registered under the U.S. Department of State’s International Traffic in Arms Regulation (ITAR). The U.S. Department of State’s Directorate of Defense Trade Controls (DDTC), under authority established by the Arms Export Control Act (AECA), administers ITAR. ITAR regulates the manufacture, export and transfer of defense articles, information and services.

ITAR registration recognizes Incodema as a manufacturer fully capable of supporting all military and homeland security projects in the U.S. In accordance with ITAR requirements, Incodema is entirely owned and operated by U.S. citizens. Incodema recognizes the critical importance of securing proprietary, classified and confidential information from foreign interests.

Fathom Manufacturing’s extensive certifications include ISO 9001:2015, ISO 9001:2015 Design, ISO 13485:2016, AS9100:2016, NIST 800-171 and ITAR.

Prototype Design Tips

Our team is here to support you in every step of the product development process. There is rarely one metal forming process that can achieve all the requirements of a design, so we also offer Design for Manufacturing (DFM) support. Our team of experts may identify alternative design features or processes that allows us to meet your specific design requirements faster and with a minimal loss of material. Feel free to reach out to our manufacturing engineers at any stage of your design process for guidance. Here are some common design requirements to keep in mind:

- Try to avoid exceeding the material maximum thickness and over-designing corners and edge conrequires. Features close to bends require a minimum 2-3x material thickness. Punching and stamping of material requires a bend relief of 1-1.5x material thickness. Stamped parts have a die break.

- Tolerances and post operations such as milling and drilling add to the project cost.

- Radii are often more economical than corner style. Use of standardized tooling inside radii of 0.01”, 0.03” and 0.06” can reduce project cost. Most parts can be formed with 0.010” bend radii, but it adds stress to the material.

- Embossing adds strength and clearance, but it can add stress or warping to the material.

- Partial shear is good for locating features, but it can cause material to be displaced from surface to surface.

- Coining adds definition and clearance, but it causes material to be displaced from one surface.

- Edge conditions will differ from process to process. Laser cut parts have a heat affected zone. Our laser machines can use specific assist gas to produce unique edge qualities.

- Laser beam widths vary from 0.010”-0.025”. Our waterjet cutter width is 0.030” and greater.

What Are the Advantages of Sheet Metal Prototyping?

Using sheet metal manufacturing technology to produce your prototype has many advantages, including:

- Precision

- Wide range of materials

- Flexible solutions

- Durability

- Budget-friendly

- Rapid turnaround

- Scalability

- Variety of finishing options and thickness

Sheet Metal Prototyping Applications

A wide variety of industries use sheet metal manufacturing to produce their prototypes and final products. Sheet metal manufacturing can be used for:

- Prototyping

- Low volume production

- Medical products

- Office equipment

- Communications products

- Housing

- Chassis

- Enclosures

- Brackets

- Appliances

- And more…

Sheet Metal Prototyping by Industry

No matter the industry, we have your sheet metal prototyping solution. Over our 20 year history, we have partnered with clients across several key industries including medical, defense, aerospace, electronics, automotive and industrial, and we are confident that our team can handle any of the technological and manufacturing challenges specific to your industry’s demands.

ELECTRONICS

ELECTRONICSWe can manufacture parts with tighter tolerances and finer surfaces that are ideal for the electronics industry.

LIFE SCIENCES

LIFE SCIENCESWe make sure that our medical parts meet the highest standards of quality and cleanliness.

DEFENSE

DEFENSEWe are an ITAR registered manufacturer and defense contract supplier.

AUTOMOTIVE

AUTOMOTIVEWe ensure that each finished part that leaves our facility meets the rigorous standards for reliability and safety that the automotive industry demands of its manufacturers.

INDUSTRIAL

INDUSTRIALWe know that durability and reliability are essential requirements when manufacturing parts for the industrial field.

AEROSPACE

AEROSPACEParts designed for the aerospace industry are designed and manufactured for durability and reliability and meet high accuracy and tolerance requirements.

Quick Turn Sheet Metal Parts

Browse examples of recently completed projects by process (such as laser cutting or press brake forming) in the gallery below. If you have any questions about which manufacturing process is best for your design, please do not hesitate to contact us.

Laser Parts

Microcut Parts

Plated Parts

Precision Forming Parts

Seely Slide Parts

Water Jet Parts

Sheet Metal Equipment

Lasers

Our lasers are known in the industry as the gold standard of laser cutter technology due to their incredible speed and accuracy.

Waterjet Machine

A waterjet cutter is a machine tool process that can cut metal and composite materials with CNC accuracy and without heat affected zones. It works by pressurizing a combination of water and an abrasive material, such as garnet, and forcing it through a nozzle onto materials to form their desired shape. Abrasive waterjets are ideal for heavy gauge and tough applications and can cut materials with a thickness of up to 6 inches in both low and high quantities.

Finishing Tool

Our technicians use this machine to deliver a great, high-quality finish in a quick turnaround time. We can even achieve a mirror-like finish with this machine.

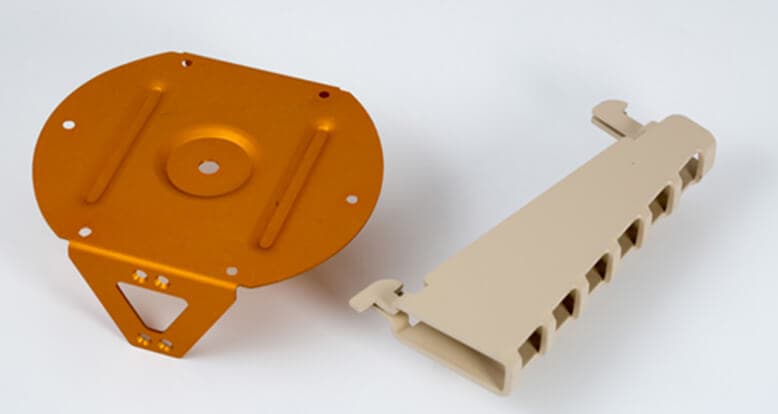

Autodeburring

Our fully automated deburring system processes up to 3 metal sheets per minute without the use of manual labor. This allows us to deburr your parts faster, which translates to faster turnaround times for you.

4 Slides

Incodema houses three four-slide machines for precision parts forming. Our four-slides are ideal for creating small parts like electrical connectors, flat springs, brackets, clips and any parts that require intricate forming. Maintaining multiple machines on our shop floor means we can produce large runs faster than most other manufacturers.

Multi Slides

We maintain three multi-slide machines on our shop floor. Multi-slide machines have eight axes, and they can produce smaller components with greater complexity than a four-axis four-slide machine. They are ideal for producing flat terminals, flat springs, brackets, clips and wire forms. These machines are also extremely efficient, and they can produce one part every two seconds.

Press Brakes

Incodema houses eight press brakes with 0.0001” resolution.

300-Ton Press

This press’s large bed size of 3’ by 6’ makes it ideal for producing large parts. It’s advanced controls and versatility make it one of our most accurate and dependable machines and reduces production time.

22-Ton Press

This press provides reliable and efficient punching, and it is powerful enough to punch through the toughest materials without sacrificing quality.

Wire EDM Machines

We have three Electrical Discharge Machines (EDM) on our shop floor. EDM is a cutting technology which uses high electrical currents to erode metal on a workpiece. EDM creates highly detailed, very small prototype parts typically made of conductive metal, and our EDMs can cut complex contours in pre-hardened steel without the need for additional heat-treating. These machines are extremely accurate with super tight tolerance capabilities, and they are perfect for precision cut parts. We also use the EDM to cut high precision tooling for your most complex formed parts.

Seely Slide Forming Tool

Developed in-house and only available at Incodema, this innovative process is similar to fully automated 4-slide and multi-slide manufacturing. This machine is ideal for low to mid-level production of parts with a material thickness of up to 0.020” and a width of 1”. It is significantly faster than manual bend press brakes and can form complex, small internal features using pre-blanked parts. With this machine, we can produce parts in minutes that take hours to form on a traditional press brake.

Seely Slide Forming Tool

This machine is the fastest laser cutter on our shop floor and is the work horse of the shop. Unlike CO2 lasers, it can cut through copper.

35-Ton Blanking Press

Our Bliss Press is perfect for mid-level production and is less expensive than traditional high volume tooling. It is capable of high speed, rapid blanking and simple, progressive automated die production. With this press, we can deliver your parts in as little as 5 to 6 weeks.

Case Studies

Working with NYC-based design firm Factioned, Ithaca-based Incodema, Inc. built the metal portion of a beer can for Busch’s #Car2Can campaign using actual parts of Kevin Harvick’s NASCAR race car.

Working with our local hospital Cayuga Medical Center (CMC), the talented team at Incodema was called to help with COVID-19 face shields. After discussions with CMC, we realized the significant challenge is that most shields are single-use or can be cleaned only a limited numer of times before needing to discard. We created solutions to this problem and have included the open-source CAD file below for your use. Send an email to sales@incodema.com for more information.

Location and Services

Incodema is located in Ithaca, New York but services all the following local areas and more: New York – Buffalo, Rochester, Utica, Mount Vernon, Syracuse, Binghamton, Elmira, Niagara Falls, Albany, Schenectady, Cornwall, Poughkeepsie and Yonkers; Pennsylvania – Erie, Scranton, Wilkes-Barre and Philadelphia; New Jersey – Newark, Jersey City and Camden. Additional areas can receive drop shipped parts or be served by other Fathom facilities that span the entire United States across the areas of additive, CNC machining, injection molding, sheet metal fabrication and over 25 different manufacturing processes.

Contact Us

Incodema

1920 Slaterville Road

Ithaca, NY 14850

Phone: 607-277-7070

Email: sales.ithaca@fathommfg.com

Fax: 607-277-5511

Related Topics

- Metal Cutting Quotes

- Sheet Metal Bending Quotes

- Quick Turn Sheet Metal

- Rapid Sheet Metal

- Sheet Metal Companies

- Sheet Metal Manufacturer

- Sheet Metal Prototype Fabrication

- Sheet Metal Prototyping

- Metal Fabrication Quotes

- Sheet Metal Quotes

- Precision Sheet Metal Fabrication

- Prototype Sheet Metal Parts

- Rapid Prototyping Quotes

- Sheet Metal Manufacturing

- Sheet Metal Shops Near Me

- Sheet Metal Fabrication Cost

- Photo Chemical Etching

- Chemical Etching Near Me

Cutting

Cutting  Precision Sheet Metal Forming

Precision Sheet Metal Forming  Mid-to-High Volume Sheet Metal

Mid-to-High Volume Sheet Metal  Post Processing & Finishing

Post Processing & Finishing