Semiconductor & Electronics Manufacturing

Computer chips are an integral part of seemingly every device today. Strong consumer demand for a world of devices is driving strong domestic demand for semiconductors and the sophisticated equipment used to fabricate them.

Manufacturers of popular devices need partners that can help them move new product concepts to market quickly and cost-effectively. Fathom is uniquely focused on supporting and enhancing our customers’ aggressive NPI initiatives.

How Can Fathom Help You with Your Semiconductor & Electronics Part Needs?

We can…

- Provide you with engineering assistance to help you optimize your designs for manufacturability, reliability and longevity.

- Help you select the best materials for each component to help ensure it provides optimal performance and longevity in your critical applications.

- Support you throughout the product life cycle – from rapid prototyping of new part designs through bridge and production manufacturing.

Leading manufacturers of semiconductor-making equipment require their suppliers to be certified to help ensure the highest levels of quality. We’ve worked hard to achieve and maintain these certifications for several manufacturers of chip-making equipment.

Fathom has cultivated a reputation for helping consumer electronics companies to bring their innovations to market, quickly and cost-effectively.

Technologies for the

Semiconductor & Electronics Industries

CNC Machining

CNC machining is used to build a variety of components used in chip fabrication equipment, including wafer holders, lift assemblies and robot arms. For the semiconductor industry, all machined parts must be specially cleaned to make them clean-room compliant. Our Austin site has the facilities and equipment to enable this service to semiconductor equipment manufacturers.

Our CNC machining service specializes in challenging applications, like working with extremely tight tolerances and exotic materials. We even work with specialized materials like Inconel and Monel, two of the world’s toughest alloys.

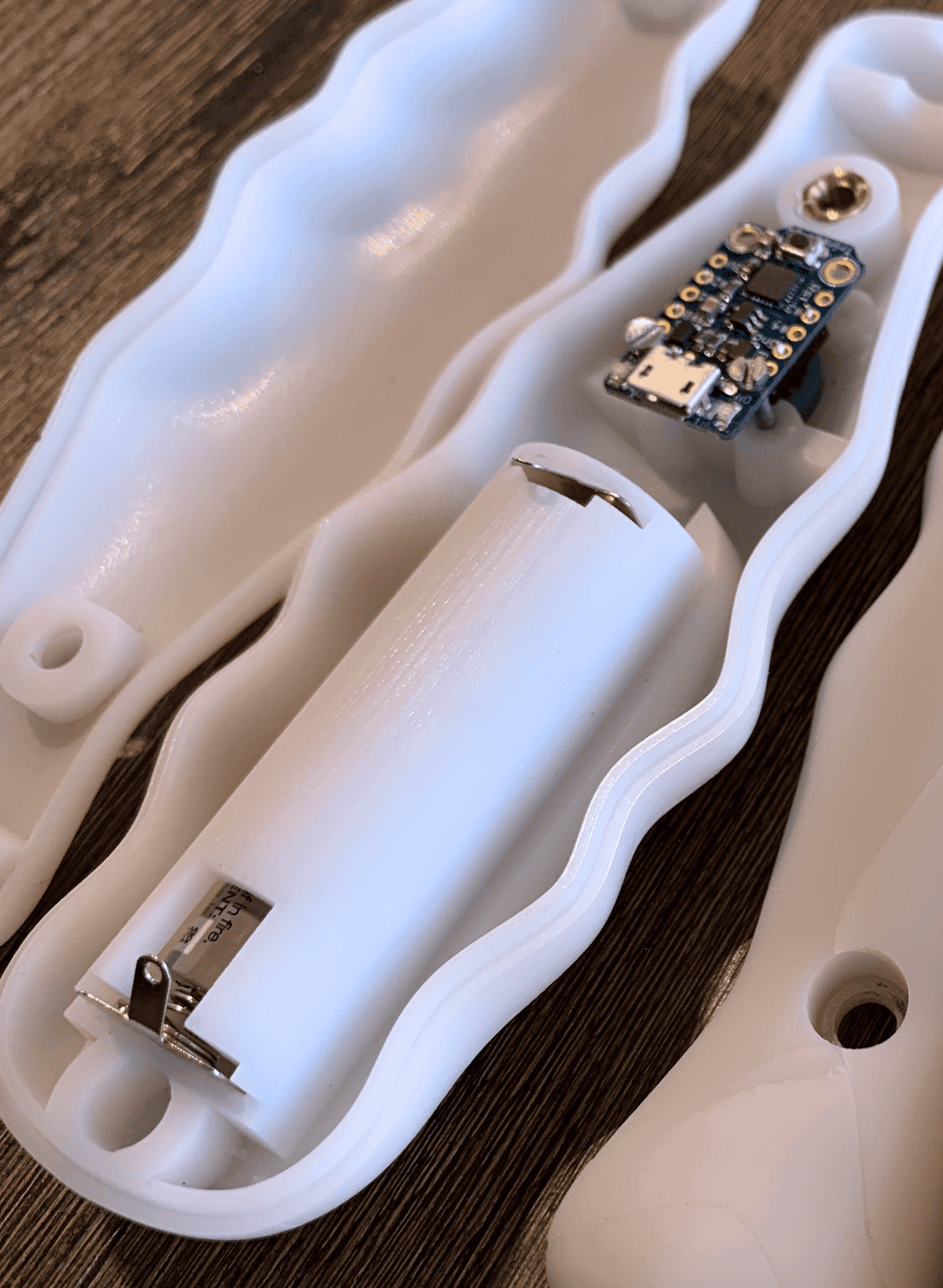

Sheet Metal Fabrication

Sheet metal fabrication services are primarily used to make complex brackets and fixtures, as well as enclosures for chip fabrication equipment and consumer electronic products.

When you need sheet metal prototype parts quickly, Fathom is ideally equipped to meet your needs. From sheet metal fabrication and precision forming of small, complex parts using a full range of cutting, forming and finishing technologies, Fathom can cost-effectively meet your requirements.

Additive Manufacturing

Industrial 3D printing services hold a lot of potential for the semiconductor industry because it enables manufacturers to create parts that aren’t possible using machining or metal fabrication. Possibilities include parts with internal cooling channels and consolidating assemblies into single parts – eliminating the need to weld parts together.

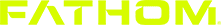

For consumer electronics, additive manufacturing can be used to quickly transform ideas into physical prototypes, helping you accelerate your new product concepts and bring them to market faster.

Fathom can produce rugged plastic parts using additive technologies like Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF). Additive metal technology, such as Direct Metal Laser Sintering (DMLS), is an ideal fit for more demanding applications. Fathom is one of the largest industrial 3D printing services in North America, with over 40 years of expertise in additive technologies.

Fathom offers a full range of post-processing services to ensure that your additive manufactured parts meet all of your cosmetic and functional requirements.

Injection Molding

For consumer electronics, injection molded parts are used to mass produce everything from enclosures to knobs and controls.

Fathom offers domestic tool-making and molding expertise as well as rapid steel tooling from China and other offshore options. We have been providing high-quality overseas injection molding with U.S. engineering and project management for over 20 years. Our customers include some of the world’s most respected manufacturers. Our company, ICOMold by Fathom is known as the low-cost leader for high-quality injection molded plastics with a fast turnaround time.

Semiconductor &

Electronics Applications

Fathom parts used in semiconductor manufacturing equipment include:

- Semiconductor wafer holders

- Robot arms and end-of-arm tooling

- Lift assemblies

Fathom parts are also used extensively in electronics equipment, including:

- Enclosures

- Chassis

- Brackets

- Tooling

- Heat sinks

- Handles

- Knobs and controls

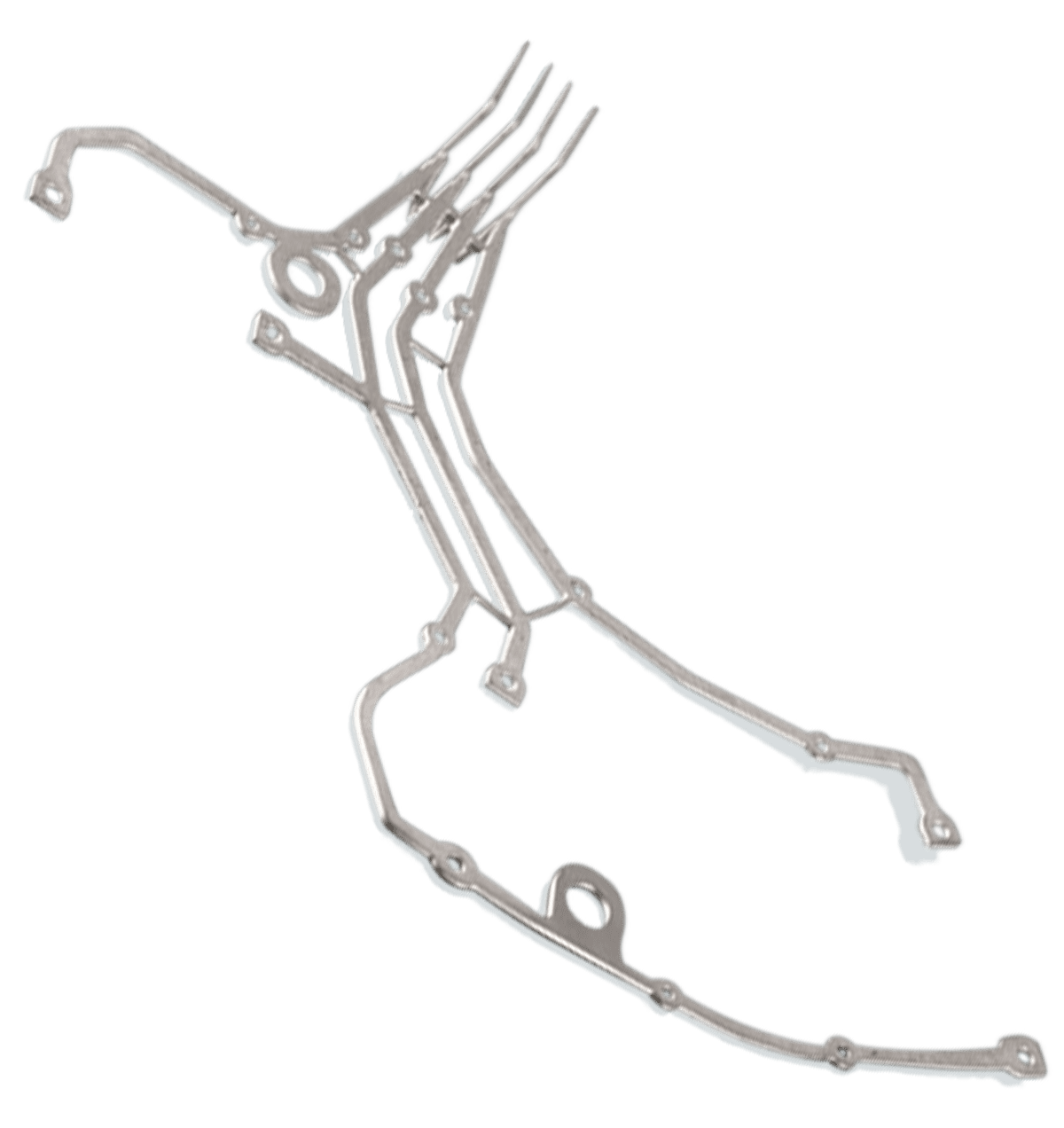

Quality is Fathom’s Number One Priority

At Fathom, our commitment to in-house inspections enables us to turn around parts quickly, including CMM validation, surface inspections and tensile strength testing.

In addition, we have a proven ability to comply with customer-specific process, material and workmanship standards.

Certifications

Visit our detailed list of Fathom certifications to view registrations held by each of our sites.

Why Choose Fathom?

- We have the technical expertise to deliver high-performance, cost-effective parts that meet your key requirements.

- We offer an unmatched breadth of manufacturing technologies — in-house, not via third parties — to meet all your needs, including sheet metal forming, precision CNC machining and injection molding. We also offer over four decades of expertise in industrial 3D printing services and seven additive technologies to meet your needs.

- We’re focused on prototyping and low-mid volume production. We’re organized to help you accelerate your design cycles, reduce new product development costs and bring your new products to market faster.

- We’re problem solvers. Bring us your complex geometries, short-run/high-mix parts and “impossible” projects. We’ll help you get the work done!

- We have a long track record of success delivering high-quality parts to a variety of leading manufacturers that serve the chip manufacturing equipment and consumer electronics industries.

- Many semiconductor equipment manufacturers source components from Asia and Europe, which can frequently result in lead time issues. They know they can count on Fathom to get them the parts they need, quickly, to help them meet their key deadlines.