Micro Water Jet Cutting

- Ideal for Complex Part Designs

- Tolerances As Tight As 0.0005 in.

- Precision Cutting with No Heat-Affected Zones

Get a Quote

Or Any of Our 25+ Manufacturing Processes

Precision Cutting

with Micro Water Jet Cutting

Precision, High Tolerance Micro Water Jet Cutting

When you need exceptional precision for your highest tolerance metal parts, micro water jet cutting can help you achieve the results you seek. Fathom’s micro water jet machines can cut materials up to 0.5 inches thick with a tolerance of 0.0005″- 0.005″. It’s faster than cutting fine features with EDM and doesn’t create heat-affected zones.

Micro water jet cutting is especially valuable for parts that require precise blanks with high tolerances that must be bent into complex shapes. Fathom’s Ithaca operation has decades of experience building custom tooling to create unique parts for discerning customers. Fathom is the only contract manufacturer in the world that can offer this advanced cold-cutting technology.

Micro water jet cutting is ideal for fast prototypes as well as bridge, low and high production applications.

Micro Water Jet Cutting // Get A Quote

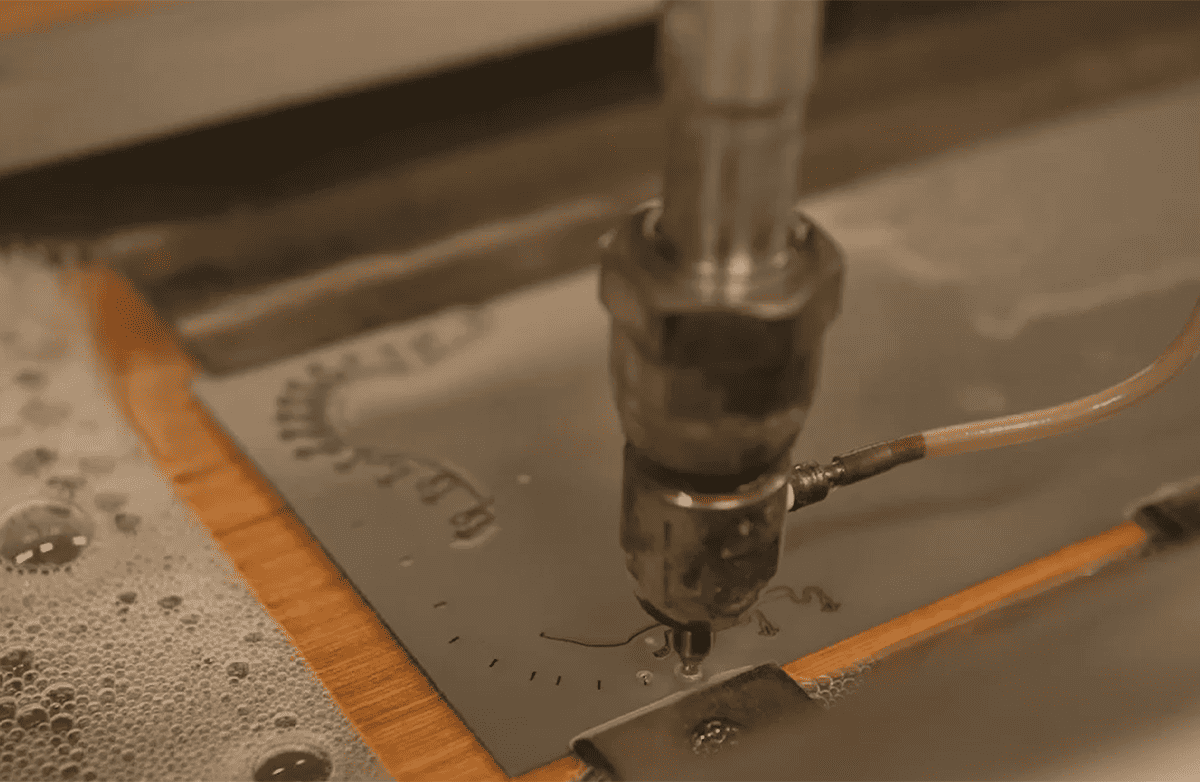

How Does Micro Water Jet Cutting Work?

Microcut™ micro water jet cutting technology is a revolutionary, abrasive waterjet technology, developed to machine flat parts in thicknesses ranging from 0.001″ to 0.125″ with incredible accuracy. It can cut features with tolerances up to .0005″. This cold-cutting method produces finished pieces with no burr, no deformations or discolorations and no heat-affected zones.

The micro water jet cutting system can also toggle between a pure water setup for softer materials such as silicone or an abrasive configuration for harder materials such as metal.

Microcut™ can also cut tight-tolerance features such as holes much faster than wire EDM technology.

What Materials Can be Processed Using Micro Water Jet Cutting?

Micro water jet cutting can process a surprisingly wide variety of materials, including:

Metal

- Stainless Steel

- Steel

- Gold

- Silver

- Titanium

- Chromium

- Nickel

- Cast Iron

- Aluminum

- Brass

- Bronze

- Copper

- Alloys

Glass

- Untempered

- Bullet-proof

- Mirror

Plastic

- Thermoplastics

- Curable

- Elastomer

- Plexiglass

Stone

- Ceramic

- Granite

- Marble

- Quartz

- Precious Stone

Miscellaneous

- Rubber

- Kevlar

- Carbon Fiber

- Fiberglass

- Graphite

Advantages of Micro Water Jet Cutting

- It can be used with a wide variety of material types

- No thermal impact or change in the material structure

- Incredible accuracy with low set-up cost

- Variable speed to maintain the vertical edge quality

- Minimal kerf

- Minimal secondary finishing required

- Efficient material usage

- Cost-effective

- Produce complex shapes

- Quick turnaround (6-8 business days)

Biggest Advantage //

No Heat-Affected Zones

Microcut™ operates without generating heat-affected zones. Superior edge quality and minimal burr is achieved, resulting in no distortion or stress. In contrast, wire EDM and laser cutting technologies are thermal processes. They can’t equal the precision of micro water jet cutting without altering the properties of the metal near the cuts.

Micro Water Jet Cutting Specifications

Microcut’s precision cutting technology provides higher cutting accuracies and tighter tolerances than standard cutting processes:

- Position accuracy 0.0001 in. (0.003mm)

- Feature and contour accuracy +/- 0.0004 in (0.01mm)

- Kerf width 0.009 in (0.2 mm) min.

- Kerf width 0.0118 in. (0.3 mm) min. with abrasive

- Maximum workpiece size 24 x 39 inches (600 x 1000 mm)

How Does Micro Water Jet Cutting Compare to Other Cutting Methods?

| Material Thickness | Tolerance | Kerf | Part Volume | Set Up Cost | Lead Time ** | Notes | |

|---|---|---|---|---|---|---|---|

| MICROCUT™ | .0005″ – 0.5″ | 0.0005″ -0.005″ | 0.009″, 0.011″, 0.0196″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, laminates, carbon fiber, ceramics, etc. |

| OMAX WATERJET | Up to 6″ | 0.005″- 0.015″ | .020″/.040″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, carbon fiber, ceramics, etc. Taper up to 59 ° |

| FIBER LASER | AL: 0.250″ SS: 0.375″ CRS: 0.500″ COP: 0.250″ Brass: 0.125″ | 0.002″ – 0.005″ | .008″ | 1 to High-Volume | Low | 6-8 days | Metals – Fast |

| WIRE EDM | 0.001″ – 6″ | 0.0005″ | 0.005″ | 1-200 Is Best | Low | 6-8 days | Conductive Metals, Carbon |

| * CHEM ETCH | 0.005″ – 0.060″ | Is +/- 10% of material thickness, .002″ min. | Equal to metal thickness | 1- Infinity | $350 Min. | 6-8 days | Metal Only. No Burrs. Beveled Edges. Half Etch and Holes. |

* Inner radius should be 100% of material thickness. Outer Radius should be 75% of material thickness.

**Dependent on geometry, volume and material: EXPEDITE options available.

Talk to an Expert

Our experts are ready to talk to you about your project. Get started today with an online quote.