Metal 3D Printing

The Next Frontier of Manufacturing

Metal 3D printing enables the economical production of high-mix, low-volume metal parts. It also allows you to create complex part designs that aren’t possible using conventional methods. Because of this, metal 3D printing services have the potential to revolutionize the manufacturing of metal components for many industries.

Igniting a Manufacturing Revolution

For years, producing short runs of metal parts via casting, machining or metal fabrication has been prohibitively expensive because of the set-up and tooling involved. Tooling for metal parts can be quite expensive and can take up to several months to produce.

Metal 3D printing services smash through this barrier by eliminating these up-front costs and enabling on-demand printing of metal parts. Because parts can be produced quickly, it opens the door to rapid prototyping, iterating part designs to test parts for fit, finish and functionality. It enables designers to simplify assemblies and create part designs that can’t be machined or cast. It can even be used for bridge production until production tooling is finished.

Metal 3D printing produces parts that are strong and durable. They can be printed using high-strength, lightweight materials like titanium, cobalt chrome and nickel alloy. They exhibit high tensile strength, hardness and wear resistance, making them suitable for demanding applications in the automotive, aerospace and medical industries.

Advantages of Metal 3D Printing

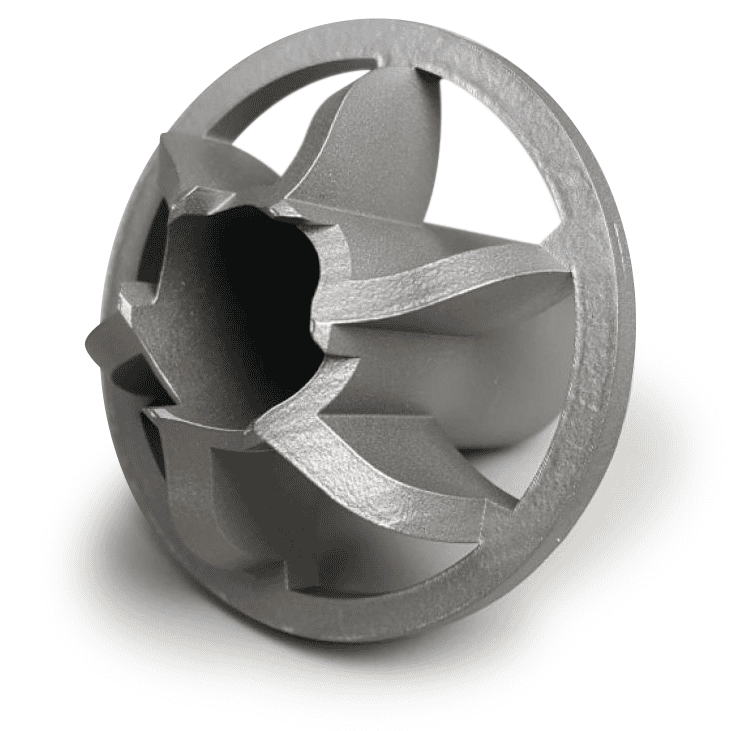

Produce Parts with Unique Geometries // Metal 3D printing services enables engineers and designers to build parts that can’t be fabricated any other way. That includes features like conformal cooling channels, channels that run just below the surface of the part, internal cavities and other complex features that can’t be machined or cast.

Rethink Metal Part Designs // Subtractive manufacturing techniques place limits on what you can create. metal 3D printing enables you to produce part designs that are difficult or impossible to achieve with traditional manufacturing techniques, such as:

- Internal supports

- Weight-saving lattice wall sections

- Conformal cooling channels

- Undercuts

- Draft angles

- Internal cavities

- Varying wall thicknesses

Part Consolidation // Thanks to the design freedom that metal 3D printing enables, you can consolidate assemblies into a single, printable part that is lighter, less expensive and more reliable.

Fast Prototyping // Metal 3D printing empowers you to iterate your prototype part designs quickly – without the need for costly tooling. You can also use it to print multiple variations of a part at the same time to determine which one offers the best functional design.

Mass Customization // No fixtures or tooling are required to produce metal 3D printed parts. That makes it easy for engineers to modify or fine-tune part designs during production. It also enables you to create multiple variations of parts as needed.

Production Parts // Need bridge production? You can use metal 3D printing services to produce several hundred production-quality parts quickly so you can keep your production line running while you wait for tooling.

Jigs and Fixtures // The exceptional toughness of metal 3D printed parts makes them ideal for jigs and fixtures for CNC machining, part inspections and more.

Industries & Applications Where Metal 3D Printed Parts are Used

Early applications of metal 3D printing include industries that require high-performance parts for demanding applications, including:

- Aerospace

- Medical

- Dental

- Automotive

Applications can include:

- Functional prototypes

- Molds and inserts

- Jigs and fixtures

- Rapid tooling

- Service parts (print-on-demand)

- Heatsinks and heat exchangers

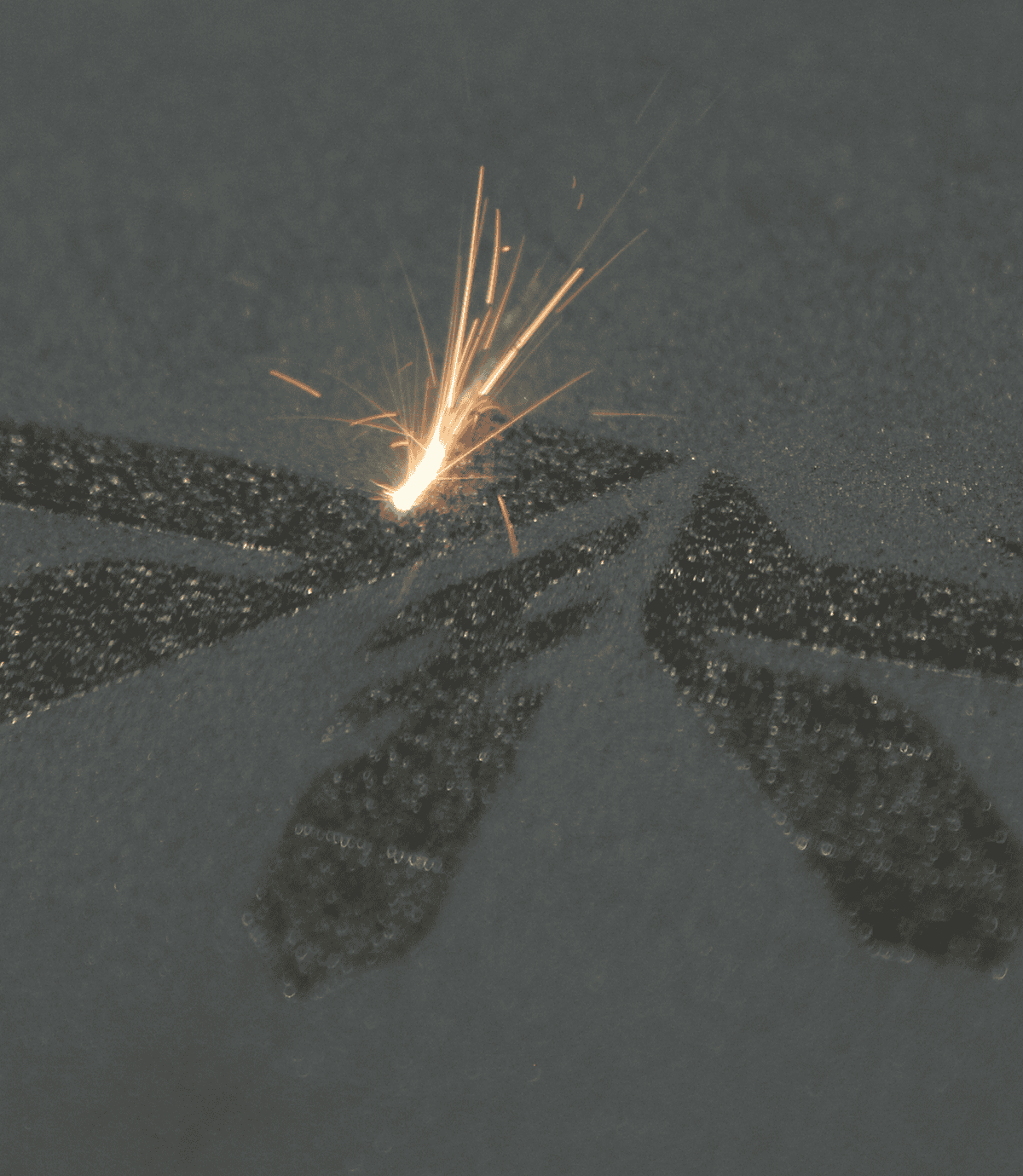

Fathom’s Metal 3D Printing Technology // DMLS

Direct Metal Laser Sintering (DMLS) is a popular metal additive manufacturing technology that uses a laser to melt 20- to 60-micron layers of metal powder on top of each other. Powdered metal is spread across the entire build platform and selectively melted to previous layers. This additive process allows metal parts to be grown out of a bed of powdered metal.

The result is a high-quality metal part that doesn’t require sintering and has the mechanical characteristics of cast metal parts. Fewer steps equal faster production – usually 5 days or less.

Because no tooling is required, parts can be produced at a fraction of the cost of custom steel tooling and fixtures.

DMLS Materials Guide

| Material | Alloy Designation | Layers | Hardness | Advantages | Applications |

|---|---|---|---|---|---|

| Aluminum AlSi10Mg | Typical Casting Alloy | 30 Micron Layers | Approx 119 ± 5 HBW | Low Weight, Good Thermal Properties | Automotive, Racing |

| Cobalt Chrome (MP1) | ISO 5832-4 & ASTM F75 | 20, 40 or 50 Micron Layers | 35-45 HRC Built | High Temperature Resistance | Turbines and Engine Parts |

| Maraging Steel (MS1) | 18% Ni Maraging 300, European 1.2709, German X3NiCoMoTi 18-9-5 | 20 or 40 Micron Layers | 33-37 HRC Built, Post Hardened to 50-56 HRC | Easily to Machine and Excellent Polishability | Injection Molding Tooling, Conformal Cooling |

| Nickel Alloy IN718 | UNS N07718, AMS 5662, AMS 5664, W.Nr 2.4668, DIN NiCr19Fe19NbMo3 | 40 Micron Layers | 30 HRC Built, Post Hardened 47 HRC | Heat and Corrosion Resistant | Turbines, Rockets, Aerospace |

| Stainless Steel (316L) | ASTM F138 | 20 Micron Layers | 85 HRB | Corrosion and Pitting Resistant | Surgical Tools, Food and Chemical Plants |

| Stainless Steel (GP1) | 17-4, European 1.4542, German X5CrNiCuNb16-4 | 20 or 40 Micron Layers | 230 ± 20 HV1 Built, Ground & Polished to 250-400 HV1 | High Toughness and Ductility | Engineering Applications |

| Stainless Steel (PH1) | 15-5 PH, DIN 1.4540 and UNS S15500 | 20 or 40 Micron Layers | 30-35 HRC Built, Post Hardened to 40 HRC | High Hardness and Strength | Prototype / Production Parts |

| Titanium Ti-64* | ASTM F2924 | 30 or 60 Micron Layers | 320 ± 15 HV5 | Light Weight, High Strength and Corrosion Resistant | Aerospace, Motorsport Racing |

| Titanium Ti-64 ELI* | ASTM F136 Properties | 30 or 60 Micron Layers | 320 ± 15 HV5 | Corrosion Resistance, Biocompatibility | Medical, Biomedical, Implants |

*Contact a Fathom expert for more information.

Cobalt Chrome MP1

Cobalt Chrome MP1

Cobalt Chrome MP1 produces parts in a cobalt-chrome-molybdenum-based super alloy. This class of super alloy is characterized by having excellent mechanical properties like strength, hardness, corrosion resistance, and temperature resistance. Such alloys are commonly used in biomedical applications such as dental and medical implants as well as for high-temperature applications such as in aerospace engines.

Cobalt Chrome MP1 Properties

- Increased Strength, Temperature and Corrosion Resistance

- Improves Mechanical Properties with Increased Temperature Resistance up to 500-600 °C

- Conforms to the Chemistry Composition UNS R31538 of High Carbon CoCrMo Alloy

- Ensures Nickel-Free (< 0.1 % nickel content) Composition

- Fulfills Mechanical and Chemical Specifications of ISO 5832-4 & ASTM F75 for Cast CoCrMo Implant Alloys

Cobalt Chrome MP1 Applications

- High-Temperature Engineering Applications (e.g. turbines, medical implants)

Maraging Steel MS1

Maraging Steel MS1

Maraging Steel MS1 is a martensite-hardenable steel. Its chemical composition corresponds to US classification 18% Ni Maraging 300, European 1.2709, and German X3NiCoMoTi 18-9-5. This kind of steel is characterized by having excellent strength combined with high toughness. The parts are easy to polish and machine with CNC finishing processes after the building process. Parts can be easily hardened in post processing to more than 50 HRC. Marging Steel applications include tooling and high performance parts.

Maraging Steel MS1 Properties

- Easy to Machine

- Age Hardening up to Approximately 54 HRC

- Good Thermal Conductivity

Maraging Steel MS1 Applications

- Series Injection Molding for High-Volume Production

- Tooling Applications (e.g., Aluminum Die Casting)

- High-Performance Parts

Stainless Steel GP1

Stainless Steel GP1

Stainless Steel GP1 has a chemical composition that corresponds to US classification 17-4, European 1.4542, and German X5CrNiCuNb16-4. This kind of steel is characterized by having good mechanical properties; excellent ductility in laser processed state, and is widely used in a variety of engineering applications. This material is ideal for many part-building applications such as functional metal prototypes, small series products, individualized products, or spare parts.

Stainless Steel GP1 Properties

- Good Mechanical Properties

- Excellent Ductility

Stainless Steel GP1 Applications

- Engineering Applications Including Functional Prototypes

- Small Series Products

- Individualized Products or Spare Parts

- Parts Requiring High Toughness and Ductility

Stainless Steel PH1

Stainless Steel PH1

Stainless Steel PH1 has a chemical composition that conforms to the compositions of 15-5 PH, DIN 1.4540, and UNS S15500. This kind of steel is characterized by having excellent mechanical properties, especially in the precipitation-hardened state. Stainless Steel PH1 is widely used in a variety of medical, aerospace, and other engineering applications requiring high hardness and strength. This material is ideal for many part-building applications such as functional metal prototypes, small series products, individualized products, or spare parts.

Stainless Steel PH1 Properties

- Very High Strength

- Easily Hardenable up to Approx. 45 HRC

Stainless Steel PH1 Applications

- Engineering Applications Including Functional Prototypes

- Small Series Products

- Individualized Products or Spare Parts

- Parts Requiring High Toughness and Hardness

Titanium Ti64

Titanium Ti64

Titanium Ti64 is a Ti6Al4V alloy. This common, light alloy is characterized by having excellent mechanical properties and corrosion resistance combined with low specific weight and biocompatibility. The ELI version (extra-low interstitials) has a very high purity. Titanium is good for aerospace and engineering applications as well as biomedical implants.

Titanium Ti64 Properties

- Light Weight with High Specific Strength Per Density

- Corrosion Resistance

- Biocompatibility

- Laser-Sintered Parts Fulfill Requirements of ASTM F1472 (for Ti6Al4V) and ASTM F136 (for Ti6Al4V ELI) Regarding Maximum Impurities

- Very Good Bio-Adhesion

Titanium Ti64 Applications

- Aerospace and Engineering Applications

- Biomedical Implants

Metal 3D Printing Finishing

There are several finishes and finishing processes that can be utilized for metal 3D printing. Options include:

Abrasive Blast (Grit & Ceramic)

Abrasive blasting removes imperfections, rust, or other contaminants from the surface of a part. It is often used in preparation for a coating application. Abrasive blasting methods include micro-abrasive blasting, bristle blasting, bead blasting, and more.

Shot Peen

Shot peening is used to add strength and reduce the stress profile of a part. Multiple shots are directed at the surface of the part. The shot peen causes deformation on the part surface. The deformation creates a compressive stressed layer that will protect the part and add durability.

Optical Polish

Optical polishing is used to create a micro-finish or super-finish on a surface for further processing. Optical polish is best used on projects with geometries in low quantities that are not tolerance dependent.

Electrochemical Polishing

Electrochemical polishing produces a mirror-like finish on metal surfaces and is sometimes used to prepare a metal part for additional finishing. The part is placed into an electrolytic solution alongside a cathode of copper or lead. An electric current moves through the solution, transferring metal ions to the part. The transferred material will smooth the surface of the part.

Abrasive Flow Machining

Abrasive flow machining is used for de-burring and polishing parts. Abrasive flow machining uses chemically inactive media. The abrasive material will polish the part and remove unwanted material.

Electroplating

Electroplating adds a metal layer to the outside of a part, increasing its strength and durability. Electroplating dissolves metal in an electrolytic solution and transfers it onto the surface of the part.

Micro Machining Process (MMP)

The micro machining process is used to produce a mirror-like finish with great technical precision while preserving the geometries of the part. The part is first mapped using a profile-meter to create a roughness profile. The part is then moved to an MMP envelope where micro-milling cutters begin to polish the part.

Why Choose Fathom’s DMLS Metal 3D Printing?

Fathom has the expertise and technology to help you meet your needs faster.

Fathom has numerous DMLS printers, making it one of the largest service bureaus for DMLS services – with deep DFAM and production expertise to match.

We also offer a wealth of post-processing capabilities under one roof – which can save you time and money.

Get a quote on your DMLS project today with our SmartQuote platform.