Fathom Engineering + Clearly Improves Eyesight

Clearly is a non-profit organization that grapples with the question: how can the whole world see? More than 700 years since spectacles were invented, 2.5 billion people suffer poor eyesight with no access to treatment. Clearly brings together people of all different backgrounds and walks of life to find solutions to the worlds sight deficit. Fathom Mechanical Engineer Miles Wilkinson was recently invited to attend a Clearly workshop in San Francisco—in this Q&A, Wilkinson talks about the collaborative session.

What was the goal of the event? Who was in attendance?

The event brought together a diversity of Bay Area-based professionals for collaborative activities aimed at identifying potential challenges and novel solutions to achieving the goal of providing individuals world-wide with quality eyesight through easily accessible eyeglasses. The activities were set up to leverage collaborative brainstorming between people with different background to spark novel ideas.

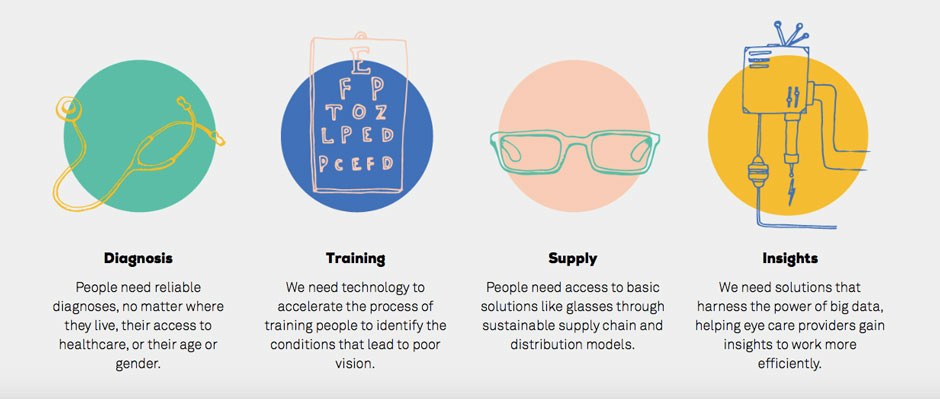

What were the major problems the event aimed to solve? How will solutions proposed by the group be instituted?

The overarching problem was that a reported 2.5 billion people world-wide do not have eyeglasses but need them in some form to improve their eyesight. However, overcoming this requires solutions to challenges such as manufacturing, social policy and awareness and distribution, among others.

Solutions proposed within the group reveal important considerations while highlighting trends and themes. Such will be compared to other similar events occurring in different areas internationally. I imagine the trends and themes collectively will help narrow the scope in ongoing actions the Clearly team will make as their initiative evolves.

What did you personally propose as a solution?

With a team of five individuals, our solution was multi-faceted but centered on localizing the manufacturing so that it would encourage a sustainable local economy. Lens manufacturing could be centrally sourced through injection molding and the frames could be made locally, thereby soaking up the local style and manufacturing techniques available. This could potentially encourage the establishment of a local manufacturing trade for new techniques.

What was the most memorable moment?

Simply how the collaborative nature with different perspectives really drives innovative ideas. Combining a doctor, engineer, designer, CFO and a public health professional brought together a full spectrum of ideas that were necessary for realistic solutions.

What did you get out of the session?

Final solutions don’t necessarily drop out of a single brainstorm session—but achieving such heuristic goals require really diverse thinking and a variety of ideas that perhaps can be integrated in the future.

Do you see a future of collaboration between Fathom and Clearly?

Certainly! If the team at Clearly requires prototyping and manufacturing for this project, Fathom has the capabilities to provide the support necessary to make the unmakeable—our experts offer the right combination of advanced manufacturing solutions so teams can go from concept to prototype to production in accelerated and innovative ways.

To learn more about ways Fathom is working with the bay area community, check out our work building prosthetics with e-NABLE or follow our social pages for more day-to-day volunteering in Jack London Square and the greater Oakland area: