Injection Molding Cost FAQs / /

Q: Does Fathom offer injection molding?

A: Yes, Fathom offers injection molding services.

Q: What is Injection Molding?

A: Injection molding is a manufacturing process commonly used for plastic parts. During injection molding, molten plastic is injected into a two-part mold using high pressure. Once the part has cooled inside the mold, it is ejected. The part may or may not require a secondary finish.

Q: Is Fathom ISO certified?

A: Fathom’s certifications include ISO 9001:2015, ISO 9001:2015 Design, and ISO 13485:2016. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

Q: Is Fathom ITAR certified?

A: Yes, Fathom is ITAR certified. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

Q: Is Fathom AS9100:2016 certified?

A: Yes, Fathom is AS9100:2016. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

Q: Is Fathom NIST 800-171 certified?

A: Yes, Fathom’s certifications include NIST 800-171. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

Q: How much does injection molding cost?

A: The cost of injection molding depends on the complexity of the part, part size, tooling cost, equipment setup and configuration, materials used, and more. Contact Fathom today for a quote.

Q: Why are injection molds so expensive?

A: Injection molds have a higher upfront cost because they can be used repeatedly to produce thousands of identical parts.

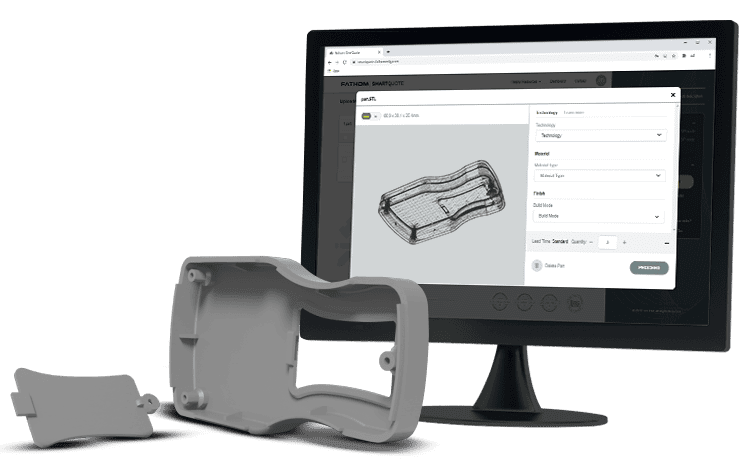

Q: How do you calculate injection molding costs?

A: The best way to estimate the cost of your injection molding part is to use the SmartQuote platform and receive a quote in as fast as 1 hour.

Q: How long do injection molds last?

A: A high-quality, well-maintained injection mold can last from 100,000 to 1 million cycles.