Across National

Time Zones

Precision manufacturing

from coast to coast.

We provide all-inclusive machine shop services. Whether your design specifications are relatively simple or highly complex, we will manage your requirements. From design assistance, metal fabrication, painting and screen printing to final assembly.

With high-precision machine shop services, we offer subtractive manufacturing processes from the first cuts to the final finishes. Machines designed for cutting, drilling, shaping, forming, stamping and more, are operated by highly skilled machinists and technical staff inside the machine shop. Everything from aircraft to engines have spent time in a machine shop. Services offered by our facility include / /

Our experts can help you find the best solution for your project.

We are a single-source supplier for custom precision parts.

Our machine shop includes painting and finishing services.

When aesthetics matter, we can add a custom design with a high-quality finish to your part.

No need to outsource assembly; we can assemble the parts in-house and have them ready to ship on time, every time.

Heavy equipment is used inside the machine shop to create new products. This requires the machine shop to be adequately ventilated and follow all necessary safety measures. Some examples of machinery that can be found inside a machine shop include:

EDM uses heat from electrical currents to cut through metal.

A milling machine uses rotary cutters to subtract material from a part.

A grinding machine uses an abrasive wheel to change the surface of a workpiece.

Drill presses have more uses than just drilling holes. They are a stationary drill that is controlled by a lever. They are capable of making holes through the workpiece.

A lathe rotates a part as it is making contact with the cutting tool. Lathes can be used for facing, sanding, knurling and more.

The bandsaw is used to make straight cuts to remove material before further processing.

For more refined finishes, buffing and deburring will produce a smooth finish on the surface of the workpiece.

The belt sander uses a moving sheet of sandpaper to produce a fine finish.

Welding is used to join metal surfaces together. Spotwelding uses copper alloy electrodes to direct a welding current to a “spot,” melting the material to join two pieces.

Multiple types of equipment may be used to polish, puff, sandblast, powder coat or paint a part.

A CNC milling machine uses different kinds of machines to complete manufacturing tasks.

In addition to machines, machine shops also host an inventory of raw materials used to make parts. The machinists may also use the machine shop to create digital designs of parts.

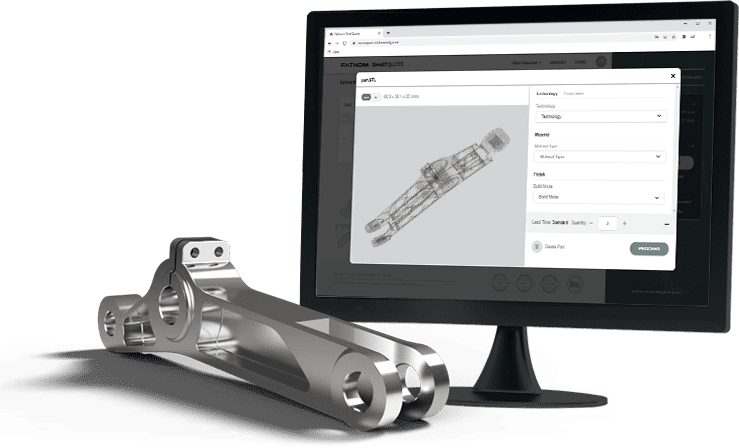

When searching for a new partner to handle your manufacturing needs, there are many factors to consider. The Fathom Digital Manufacturing can be the single-source supplier of custom precision sheet metal or machined products. Our experts will exceed your expectations, from design assistance to metal fabrication, painting, screen printing and final assembly. We are dedicated to being the best in the industry and delivering the highest quality products and services on time. Our services include / /

Our management of projects is sophisticated. Quality, costs, methodology and scheduling are meticulously monitored and controlled. From design assistance provided by our in-house development team to the integrated manufacturing processes and delivery of the product, customer satisfaction is assured. Through an on-going progressive attitude and meticulous Continuous Improvement initiatives, we are dedicated to being the industry’s very best in machine shop services. We are absolutely committed to continually creating and maintaining an atmosphere for total success.

Through concurrent engineering, we work in partnership with you to find the single best approach. Our objective is to meet your needs. While our attention is ultimately centered on quality performance, our principal focus is always customer satisfaction.

This single-source capability reduces the overall time required for manufacturing and frequently allows for departments to coordinate purchasing, scheduling and deliveries. Perhaps the most important benefit is the increased level of value engineering the experts at Fathom provide at every stage of the manufacturing process.

Fathom is proud to offer a wide range of tooling to meet nearly any customer specification. If your design has unique requirements, tooling can be developed to meet your needs.

Ready to start your project and incorporate our all-inclusive services? Contact us today for your custom quote.

Precision manufacturing

from coast to coast.

HEADQUARTERS //

1050 Walnut Ridge Drive

Hartland, WI 53029

877-328-4668

ARIZONA

444 W. 21st St. Ste. 101

Tempe, AZ 85282

480-966-2300

CALIFORNIA

46758 Lakeview Blvd

Fremont, CA 94538

COLORADO

7770 Washington St.

Denver, CO 80229

303-288-6855

FLORIDA

14000 N.W. 58th Court

Miami Lakes, FL 33014

305-889-3280

ILLINOIS

1207 Adams Drive

McHenry, IL 60051

815-385-7500

1401 Brummel Ave

Elk Grove, IL 60007

847-952-8088

MINNESOTA

13758 Johnson Street NE

Ham Lake, MN 55304

763-755-7575

NEW YORK

1920 Slaterville Rd.

Ithaca, NY 14850

607-277-7070

401 W. Shore Blvd.

Newark, NY 14513

315-331-7680

TEXAS

1513 Sam Bass Rd.

Round Rock, TX 78660

512-255-1477