3D Printed Electromagnet / / 3D Printed Coil – Fathom

Electronics designers and engineers are in a race to develop new and differentiated products and 3D printing can be that competitive advantage to push ahead.

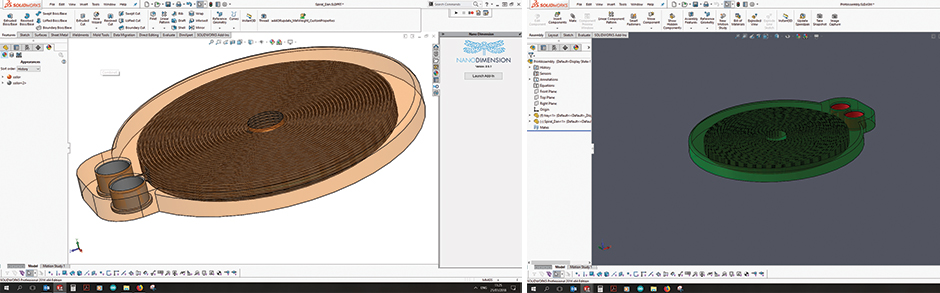

The unique capabilities associated with 3D printed electromagnets makes it possible to customize the physical shape and size to enable affordable prototyping for experimental applications. Limitless shapes and sizes can be created using 3D printing to fabricate electronics to accommodate specific project needs and enable more precision. With the DragonFly Pro 2020 designers and manufacturers can create new ‘beyond-PCB’ applications for electronic products far past what was possible with standard electromagnets. This opens up a world of opportunities for innovation in the electronics industry, as well as increasing greater adoption of electronics fabrication by way of 3D printing and additive manufacturing. Check out the example below.

| Trace Size | 100x100um |

|---|---|

| Number of Layers | 12 |

| Number of Wraps (Turns) Around Each Layer | 30 |

| Distance Between Layers | 100 micron (4 mil) |

To see this one in action, check out the video below—filmed at Fathom with Simon Fried of Nano Dimension. Approximately three minutes and 30 seconds in, Fried demonstrates the functionality of a 3D printed electromagnet coil. The coil was 3D printed using the DragonFly 2020 Pro 3D Printer for professional electronics.

FEATURED NANO DIMENSION VIDEOS

You can also watch a video recently posted on YouTube by Nano Dimension // Download the PDF //

With this advanced 3D printing technology, it is possible today to develop a wide range of powered devices from antennas, touch sensors and electric doorbells to motor generators and transformers. Talk with a Fathom specialist to learn more about electronics 3D printing by Nano Dimension. For even more information about what 3D printing can do for agile electronics development, watch the hour-long seminar below.

FEATURED ON DEMAND WEBINAR

Held on November 29, 2017 at Fathom’s Oakland-based headquarters and production center, Fried of Nano Dimension talked about 3D printing electrically functional circuitry, what organizations are doing with the technology today and near-future application advancements. In this recording, learn more about how teams today can utilize agile development processes at every prototyping stage to speed up time to market and increase product innovation.