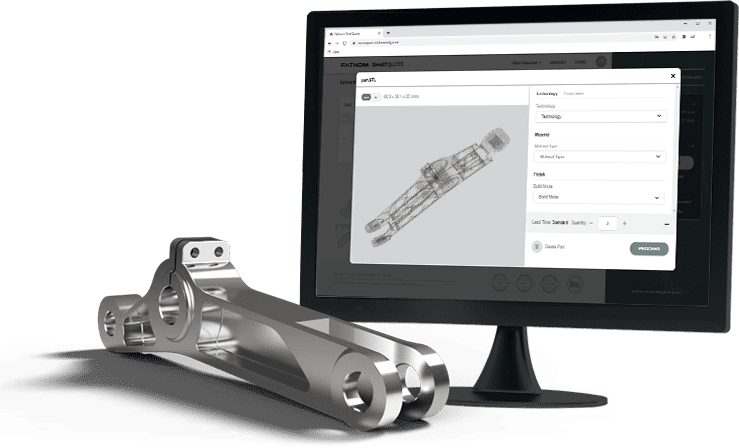

As an experienced manufacturer, Fathom is ready to partner with you on your acrylic CNC machining project. Whether your project is time-sensitive, complex, requires precision or is short production run related, Fathom can handle it. CNC machining is just one of the many manufacturing technologies offered by Fathom. Get started today.

Acrylic is a thermoplastic raw material sometimes referred to as polymethyl methacrylate (PMMA). Acrylic is transparent and is commonly used as a replacement for glass. When acrylic is CNC machined, a computer controls the machinery, directing it to subtract raw material and form the part. CNC technology with mills, lathes, routers, grinders and other manufacturing equipment.

Acrylic has many advantageous properties that make it excellent for CNC machining. In addition to being more transparent than glass, acrylic is UV resistant, dimensionally stable and has good abrasion resistance. Acrylic can be polished and is available in multiple colors. PMMA is considered biocompatible and can be recycled.

Acrylic is a popular manufacturing material for multiple reasons. Some of the properties of acrylic include:

Work with Fathom on your next CNC machining job. Fathom offers many CNC services, including CNC 3 & 5 AXIS, CNC milling and turning, sinker EDM, wire EDM, Swiss machining and more. As part of our comprehensive services, we also offer finishing and post-processing. CNC machining is just one of 28 manufacturing services.

Fathom’s manufacturing facilities are powered by over 530 machines, including mills, lathes, presses, press brakes, turret punches and additive systems. Fathom has equipment dedicated to metal prototype fabrication, including lasers, waterjet machines, finishing tools, autodeburring, 4 slide machines, multi-slide machines, press brakes, 300-ton presses, 22-ton presses, wire EDM machines, seely slide forming tools and 35-ton blanking presses.

Fathom provides not just CNC machining but also hybridized services leveraging prototype fabrication and additive manufacturing. Need metal prototype fabrication as part of a more complex project? Fathom can handle it. A recent case study is listed below where Fathom delivered 20,000 parts in 27 days using 55+ tools, including metal prototype fabrication services:

A customer came to Fathom with a complex project that spanned the technologies and processes of rapid production—and needed it done fast. Fathom delivered.

55+ Tools to Injection

Mold 15,000 Parts

First Article in 2 Weeks

3,000+ 3D

Printed Parts

2,000+ Metal

Fabricated Parts

3D Printing / Additive Manufacturing—PolyJet, SLS, MJF.

DFM Analysis + CAD Mods.

CNC Machining. Laser Cutting.

Stamping. Die Cutting. Post-Opp Drilling.

24-hour Turnaround Urethane Casting.

Injection + Compression Molding.

Model Finishing. Insert Assembly.

Advanced Project Management.

Fathom’s manufacturing network has nine locations across the United States with CNC capabilities. Our CNC locations are:

HEADQUARTERS

1050 Walnut Ridge Drive

Hartland, WI 53029

ISO 9001:2015

AS9100:2016

ITAR

ARIZONA

444 W. 21st St. Ste. 101

Tempe, AZ 85282

ISO 9001:2015

NIST 800-171 Compliant

ITAR

CALIFORNIA

620 3rd Street

Oakland, CA 94607

ISO 9001:2015 Design Certified

NIST 800-171 Compliant

ITAR

ILLINOIS

1207 Adams Drive

McHenry, IL 60051

1401 Brummel Ave

Elk Grove, IL 60007

ISO 9001:2015 Design Certified

MINNESOTA

13758 Johnson Street NE

Ham Lake, MN 55304

TEXAS

1513 Sam Bass Rd

Round Rock, TX 78681

ISO 9001:2015

ISO 13485:2016

A: Yes, Fathom offers CNC services.

A: CNC machines are computer-driven manufacturing equipment.

A: Yes, Fathom is ISO 9001: 2015 certified. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

A: Yes, Fathom is ISO 13485:2016 certified. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

A: Yes, Fathom is NIST 800-171 certified. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

A: Yes, Fathom is ITAR certified. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

A: Yes, acrylic can be CNC machined.

A: Yes, acrylic can be engraved with custom designs using CNC technology.

A: A CNC mill uses a cutting tool to remove material along multiple axes. Acrylic can be cut using a CNC mill.

A: A CNC router can be used to cut acrylic. The acrylic should be secured during the process, and a larger, specialized bit should be used.

Do you need an estimate on an upcoming CNC machining project? Get a fast quote on any CNC file.

Precision manufacturing

from coast to coast.

HEADQUARTERS //

1050 Walnut Ridge Drive

Hartland, WI 53029

877-328-4668

ARIZONA

444 W. 21st St. Ste. 101

Tempe, AZ 85282

480-966-2300

CALIFORNIA

46758 Lakeview Blvd

Fremont, CA 94538

COLORADO

7770 Washington St.

Denver, CO 80229

303-288-6855

FLORIDA

14000 N.W. 58th Court

Miami Lakes, FL 33014

305-889-3280

ILLINOIS

1207 Adams Drive

McHenry, IL 60051

815-385-7500

1401 Brummel Ave

Elk Grove, IL 60007

847-952-8088

MINNESOTA

13758 Johnson Street NE

Ham Lake, MN 55304

763-755-7575

NEW YORK

1920 Slaterville Rd.

Ithaca, NY 14850

607-277-7070

401 W. Shore Blvd.

Newark, NY 14513

315-331-7680

TEXAS

1513 Sam Bass Rd.

Round Rock, TX 78660

512-255-1477